Sensors are used in many different medical applications, and while they’re relatively simple devices, there are many things you might not know about them. Here are some of the most frequently asked questions regarding Maxtec oxygen sensors. Looking for a specific sensor? Find a comprehensive list of our sensors and their specifications here.

How customized can we make sensors?

Connectors: The customizability is fairly wide open. If you don’t have a connector we’re already using, it’s not very difficult to make something new for your unique application. The process of customizing connectors is typically a 2-3 month process.

Voltage output: This is more difficult to customize than connectors. Our ranges are around 8.5 to 17mv because we have the components available to cover this range. Anything outside of this range would include R&D time, which could be around a 6 month project.

Response Time: We don’t have a lot of flexibility in regards to customizable response time, as Maxtec mainly specializes in 15-second response time. While we do buy/sell sensors with faster response times, we specialize in 15.

End-of-Life Dates: We offer two different life sensors, the Max-125 series, which is 500,000 %o2 hours with a warranty of 1 year, and the max 250 and 550, which are 1.5 million %o2 hours, with a 2 year warranty. Our sensors function similar to that of a battery, where the more you use it, the shorter it lasts.

Labeling: Labeling can get a little tricky. For customers in the industrial market, it probably wouldn’t be a problem to get custom labeling, but it’s not possible with medical services due to new regulations.

Shape and threads: Getting customized shapes and threads is doable, but it’ll be a long process.

For more information and to see how we can help you, contact us at [email protected].

How do they actually work?

Maxtec oxygen sensors are galvanic fuel cells, consisting of a lead anode, gold cathode, and weak acid electrolyte. A gas porous membrane is bonded to the gold electrode. Oxygen permeating through the membrane is electrochemically reduced at the gold electrode and concurrently the lead anode is oxidized. The current generated due to this reaction is directly proportional to the partial pressure of oxygen at the sensing surface of the cell. A resistor network, including a thermistor for temperature compensation, applied in parallel across the anode and cathode produces a voltage output signal proportional to changes in oxygen concentration. This signal is used by instruments to convert a voltage to a corresponding oxygen concentration. You can watch a video that shows this reaction here.

How are we supposed to store the sensors?

Sensors should ideally be stored between 5 – 25°C (41 – 77°F). Use first-in, first-out (FIFO) inventory management to keep sensors fresh. Red oxygen barrier tape can also be used to restrict the available oxygen level to about 7% to preserve the life of the sensor.

Does temperature degrade the sensor?

Elevated temperatures increase the rate of the chemical reaction inside the sensor and will decrease the life. The rate of reaction doubles around 45°C (113°F).

Does humidity play a part in degrading the sensor?

Generally no, unless the sensor is used or stored in extremely dry conditions, where it may begin to dry out the sensors electrolyte.

Does altitude play a part in degrading the sensor?

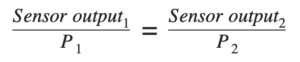

Sensors are sensitive to the partial pressure of oxygen. This means they will be affected by pressure changes due to changes in altitude. There is a direct relationship as shown here:

Do temperature and humidity change the readings on the sensor?

Temperature – Sensors are compensated for temperature effects using an NTC thermistor network and are generally affected less than 3% O2 across the operating temperature range.

Humidity has a minimal effect on the sensor readings. However, humidity should not be allowed to condense on the sensor face.

Are Maxtec sensors compatible with non-Maxtec devices?

Generally yes, but you should consider the connector, sensor output, response time, and life in your evaluation. Maxtec produces thousands of sensors both for OEMs as well as replacement sensors for a variety of applications.

What are the average costs of a Maxtec sensor?

Maxtec sensor prices can vary based on the difference in how they’re made and their capabilities. However, most sensors are around $100. For sensor pricing, you can visit Shop Maxtec, or fill out this form to get in contact with a Maxtec representative.

When does the warranty start?

Maxtec warrants the MAX-250 oxygen sensor to be free from defects in material and workmanship for a period of two-(2) years from Maxtec’s dated of shipment. Based on Maxtec’s product evaluation, Maxtec’s sole obligation under the foregoing warranty is limited to making replacements or issuing credit for sensors found to be defective. Should a sensor fail prematurely, the replacement sensor is warranted for the remainder of the original sensor warranty period.

What is the red tape for?

Red tape is used during shipping and/or storage to preserve the life of the sensor. The oxygen barrier tape restricts the available oxygen level during storage to about 7%, preserving the sensor life.

Why do I need to let the sensor stabilize before using it?

This is generally not required, unless the sensor or device has been stored in an extremely cold or warm environment. In such a case, it is advised to allow time for your sensor and device to reach thermal equilibrium. For sensors with red tape, it’s recommended to wait about 15 minutes after removing the tape to allow the sensor to reach equilibrium with the room air concentration before calibrating and placing the sensor into use.

Do you have to add power? How is the device powered?

Maxtec oxygen sensors are self-powered, so no extra power is required. An easy way to visualize our sensors is that they’re essentially a battery. However, our ultrasonic sensor, like that inside of our UltraMax, requires power but it doesn’t run out.

Are there any toxic materials inside the sensor?

Like a car battery, most Maxtec sensors contain lead, but it’s sealed and self contained. For this reason, used sensors should not be disposed of in a normal trash bin. Sensors should be disposed of as lead waste or returned to Maxtec for free environmental disposal. Lead-free alternatives are currently in development.

When is the free sensor/frequent buyer campaign coming back?

The frequent buyer campaign was originally a limited-time promotion. Due to its popularity, Maxtec may consider doing something similar in the future.

How long do they last? What is the lifetime?

Maxtec sensors generally last 1-2 years in normal-use conditions, but we’ve seen some go as long as 8 years in some applications.

Can I use a Maxtec sensor when I have another brand of analyzer, such as Analytical Industry or Precision?

Most likely, but you should consider the connector, sensor output, response time, and life in your evaluation. Maxtec produces thousands of sensors both for OEMs as well as replacement sensors for a variety of applications.

Can you use it in anesthesia machines and all ventilators?

Generally yes, but you should consider the connector, sensor output, response time, and life in your evaluation. Maxtec produces thousands of sensors both for OEMs as well as replacement sensors for a variety of applications.

If I keep the sensor refrigerated will it last longer?

Yes, when refrigerated the internal reaction slows down and will prolong the life of the sensor. However, this usually isn’t worth the effort. We generally don’t recommend storing sensors below 5°C (41°F).

What is the shelf life of a sensor?

Sensors aren’t given a specific shelf life, but since the sensors are continuously being depleted even when not in use, we recommend installing the sensor into the application within 3 months after receipt. Most sensors are warrantied for 2 years, which begins from the date of shipment.

What are the variations of sensors available?

Oxygen sensors are not standardized and, though all sensors operate under the same working principles, a variety of sensor styles exist to accommodate the different connectors and outputs required for different applications. You can reach out to us at maxtec.com/sensor-advantage for help finding the right sensor for your unique application.

What’s the difference between different sensor types?

Sensors are similar to batteries. Different sensor types exist for various applications to cover different connections, response times, and output requirements, but in general they all function exactly the same.

Why would one be better than another?

The Max-250 and Max-550 series sensors have higher internal volumes than typical sensors, which lead to longer lifetimes. They also utilize a novel weak acid electrolyte which is able to last longer and provide an increased lifetime vs a typical KOH electrolyte sensor. For more information visit maxtec.com/sensor-advantage.

What gases affect sensors negatively?

In regards to our weak acid line — the Max-250 and 550 — it’s a case-by-case basis for all our sensors. It’s helpful to check the specifications for each sensor to see the gas interference. If the gas you are interested in isn’t listed, you can request a sample to test it with your application.

Are there lead-free options?

Lead-free options are currently in development as we are working on a lead-free replacement for our Max-250 product line. Date TBD.

What are some common failures and why?

A common failure is that when the sensor life runs out, the voltage output level will drop. Our instruments and customers instruments that use our sensors look for a certain voltage output, and if it’s not within a certain range it’s at the end of its life. Maxtec O2 sensors are also pressure-sensitive, so if the ambient pressure changes, the device needs to be recalibrated. An elevation change of about 500 feet should constitute a recalibration. Extreme temperature changes can also cause failure, which sensors should then be recalibrated. Connection is another common failure, and in most cases it’s due to the sensor not having a secure connection. It’s important to make sure the connector is secure, which is made easy with our locking thread capped sensors.

What are the methods of packaging the sensors?

We offer two different packaging configurations. The standard is the blister pack for individual sensors. The other option is bulk packaging.

To find the sensor that’s right for your application, visit maxtec.com/sensor-advantage and fill out the form to get in contact with one of our knowledgeable representatives.

If the question you’re looking for was not answered in this list, please reach out to us at [email protected]